Have you ever wondered what types of questions people “Ask a TRI Expert“? This series, brought to you by the Tile Roofing Institute, allows anyone to ask anything about tile roofing installation, maintenance, etc. The Tile Roofing Institute (TRI) is a non-profit association of producers and associates of concrete and clay tile and is considered one of the leading experts in the industry. Here’s a recent question from a home inspector, and the response from TRI President and Technical Director, Rick Olson.

The high wind tables in the Tile Roofing Institute’s Concrete & Clay Roof Tile Installation Guide can be intimidating at first glance. A recent “Ask the Expert” response by TRI President and Technical Director Rick Olson describes how to use the tables to determine fastening requirements.

Question:

“Oklahoma is considering changing to a 115mph wind zone. I need help to decipher the tables in the back of your TRI manual so to know how to use these on an install.”

Response:

Although they seem onerous at first glance, the wind tables are not too harrowing to navigate with a few clues.

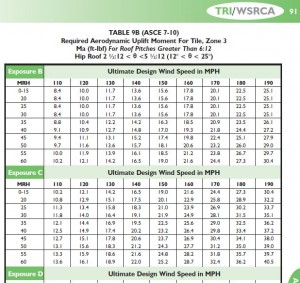

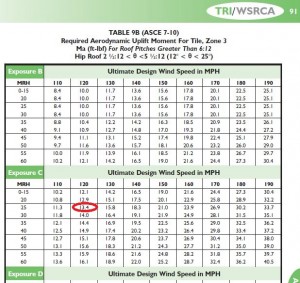

If Oklahoma is considering the 115 MPH designation, we will assume they are going with the 2012 IBC/UBC and the tables in Appendix C would apply. Since most tiles are installed on Gable/Hip roofs we would be looking at Tables 9A (roof slopes 5.5:12< 6:12), Table 9B (roof rlopes 2.5:12<5.5:12, shown below) or Table 9C (roof Slopes 6:12< 12:12).

This will let us know what the wind uplift would be on the tiles. Since you are 115 MPH, you would use the 120 MPH column for exposure C (most commonly used outside of coastal areas).

*Example: 5:12 hip roof at 25-ft. mean roof height, exposure C is 13.4 ft-lb of resistance (from Table 9B).

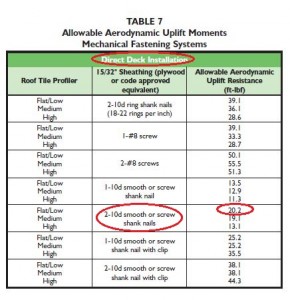

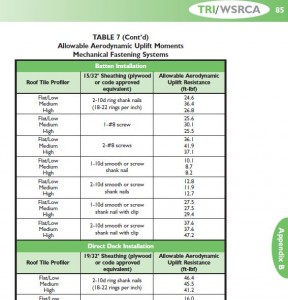

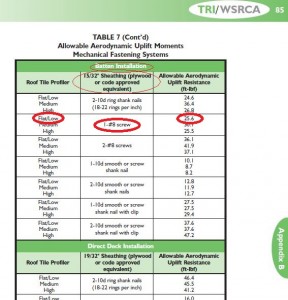

Now we need to go to Table 7 on page 85 (since Table 2 on page 95 only has the very high wind options that are above your 120-mph cutoff).

Here we list all of the fastener options and their corresponding resistance. You need to select the tile profile. So let’s say a flat tile on a batten on a 15/32” sheathing.

We need an option that will exceed the 13.4 so we will be looking at the 1-#8 screw at as a minimum with 25.6 in Table 7.

If you were a direct deck application with a 15/32” sheathing, you could use the 2-10d smooth shank as a minimum with 20.2